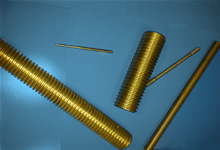

Comasmo Tek - Examples thread rolling pieces.

This technical page briefly summarizes all the various jobs our thread rolling machines are able to perform. For any further information or projects, please feel free to contact us.

THREADING – ROLLING MACHINE + THREAD ROLLING DIES

Cold forming of steels, including stainless steel or tubes/pipes for metric threading whitworth, trapezoid, acme or special customized from diameters from 2 to 60 mm, with cylindrical or tapered profile.

TOOTHING – ROLLING MACHINE + TOOTH ROLLING DIES

Cold infeed (plunge), thru-feed forming or using incremental system, fixed claw clutch or sliding claw clutch according to unified table profiles or special drawings.

KNURLING – ROLLING MACHINE + KNURL ROLLING DIES

Cold forming of steels, including stainless steel or tubes/pipes for straight, helical or criss-cross teeth knurls with pitches between 0.4 mm and 2.5 mm on cylindrical or tapered pieces.

LAPPING – ROLLING MACHINE + LAP ROLLING DIES

Constant super finish with cold forming principle with smooth steel rollers, including stainless steel for rods or also spherical profiles to obtain finishes, including with 0.04ra roughness, and increase in surface resistance. Particularly suitable for sliding pieces.

PIPE SHAPING – 3 DIES ROLLING MACHINE + SHAPE ROLLING DIES

Cold forming on small or large thickness tubes/pipes to make splines or shaped profiles in general, according to customer specifications.

INTERNAL THREADING – INTERNAL ROLLING MACHINE + DIES

Cold forming performed inside the holes of pipes or flanges to obtain threads of various types, blind or through.

WORM SCREWS – ROLLING MACHINE + THREAD ROLLING DIES

Cold forming of worm screws with one or more threads and various lengths and forms, to achieve better screw profile finish and increase in piece strength thanks to the compression of the material fibres, compared to traditional removal methods which simply cut the fibres.

COMASMO TEK srl | Address: Via L. Manara 31, 20900 Monza (MB) | P.IVA 06729890969 |Tel. (+39).039 2307170 Fax. (+39).02 2135160 | Email: info@comasmotek.it

R.802 - 10 TON.

R.802 - 10 TON.